CONVINCING SOLUTIONS

The integration of corrugated cardboard production, corrugated cardboard processing and the production of foam parts generate mutual benefits for all business units and our customers through the permanent transfer of expertise. It is a solid basis for the successful development of diverse packaging solutions.

Corrugated cardboard DENOWELL®

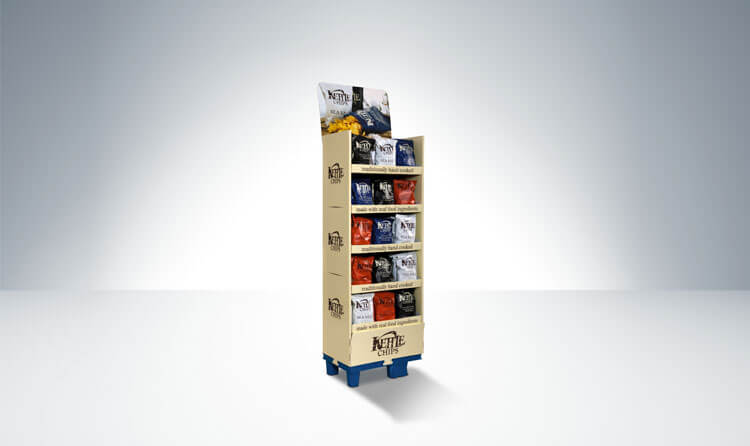

When goods need to be optimally protected whilst travelling, corrugated cardboard is the ideal logistics partner. But it also ensures an effective advertising presence as a marketing instrument directly at the “point of sales”. Corrugated cardboard is almost 100% recycled and is therefore an exemplary recycled product.

At DELKESKAMP we produce folding boxes and die-cut packaging made of corrugated cardboard in the flute types C, B, D, E and their various combinations (double flute). However, an open shaft is also possible. Our packaging can be printed in offset high quality flexo as well as in pre-print.

Information on corrugated cardboard

Your specialist for high-quality, environmentally friendly produced corrugated cardboard!

Wide range of applications, inexpensive production and durable in use: corrugated cardboard is a real all-rounder. According to the current standard DIN 55468 T1, corrugated cardboard is defined as a special packaging material which is produced from one or more plies of corrugated paper. This in turn is glued between further layers of other paper. This production technique guarantees a low dead weight on the one hand, but good durability on the other hand. Here at DELKESKAMP you will find individual packaging solutions. We use our professional expertise and many years of experience to offer you exactly the solution that will efficiently help your company with the desired project.

Corrugated cardboard in various flute types, refined with printing

DELKESKAMP has specialised in individual corrugated cardboard to meet customer requirements. All our products are also manufactured using the most modern technology in a particularly environmentally friendly manner. We offer packaging options such as die-cut packaging, tray, folding box or larger folding cartons. Corrugated cardboard is offered in the types E, D, B, C and the respective combinations. We offer open shaft here as well as packaging for vending machines and FEFCO 0201.

Additionally, we provide you with the possibility to refine the corrugated cardboard subsequently. This can be done, for example, by means of high-quality flexographic printing, where your logo, inscriptions, slogans, etc. can be accomplished with up to six colours. Preprint and offset printing are also available as further options. As an experienced manufacturer, we would be pleased to advise you comprehensively which of these variants is particularly suitable for your intended use and how the production of corrugated cardboard is carried out in order to make sure you obtain an individual product of outstanding quality.

Corrugated cardboard can be used in many ways

The innovative packaging is an excellent solution, especially for sensitive and fragile goods, which are very well protected by it whilst being transported. Thanks to individual customisation, corrugated cardboard can be specially adapted to the respective product and packaging and is also often used within the packaging as a cushioning element for transportation. Alternatively, printed corrugated cardboard could be integrated into the in-house marketing concept. At the point of sale, it can capture the interest of potential customers, is informative and can be disposed of quickly later if required.

Confidence in sustainable quality, the various possibilities of use and, at the same time, countless models with individual character, which you can order directly from DELKESKAMP in different quantity ranges. Regardless of whether you wish for a certain product type or to rely on a combination instead, DELKESKAMP corrugated cardboard convinces day after day anew with its high quality, low dead weight, excellent processing and of course its environmental friendliness. Contact us today if you are in search of individual corrugated cardboard for your company or looking for a specific application.

Folding cartons

For goods of any kind: DELKESKAMP folding cartons made of robust corrugated cardboard

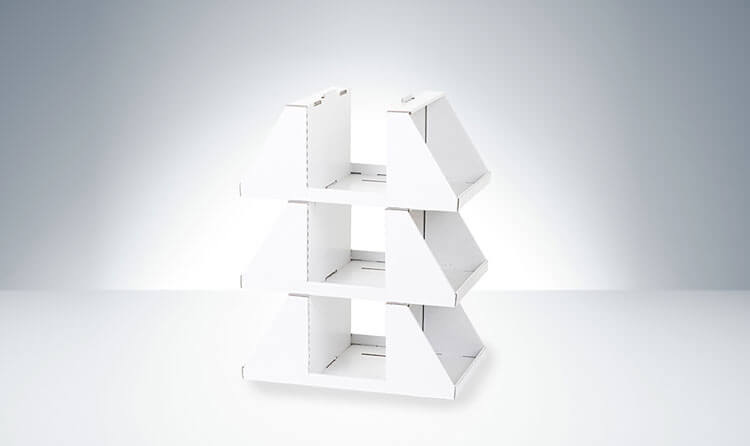

Folding cartons are indispensable in industry and commerce. In both the B2B and B2C sectors, goods and merchandise are sent on (long) journeys in folding cartons of various sizes. Consequently, these folding cartons must be very robust. But they should not be oversized either, because then they would no longer be inexpensive and economical. In order to achieve this, DELKESKAMP offers you robust folding cartons made of corrugated cardboard, which are individually adapted to your requirements. We make sure that you find just the right design to fit your wishes and desires. As experts for trays, vending machine packaging, folding boxes, die-cut packaging, displays and many other types of packaging, we would be pleased to advise you. All packaging can be printed in offset, flexo or preprint. Please also ask us about digital printing.

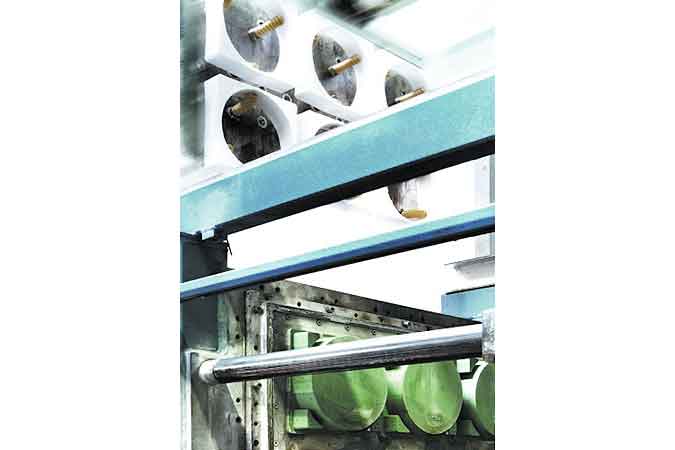

Folding cartons are produced at DELKESKAMP according to customer-specific requirements

It is our modern and extremely advanced production facilities that guarantee individual production according to the customer's wishes. With our corrugators, we already produce the raw material in such a way that it is ideally suited for the subsequent processing steps. Thanks to the perfect selection of the papers in combination with the appropriate type of corrugation and design according to your requirements, we achieve first-class technical values in terms of product protection and transport safety for your goods traffic.

We achieve high-quality and sophisticated designs by means of elaborately glued boxes up to a maximum of 6-point gluing. Despite ideal protection and high-quality printing, the corrugated cardboard powerhouse is still lightweight and flexible in use. Whether large, small, light or heavy consignments - the folding carton is ideally suited to the requirements.

DELKESKAMP machinery produces high quality folding cartons

Our machine park is broadly based. After the cardboard has been produced on the corrugators in the shape of formats or machine sheets, it is further processed into folding cartons or die-cut packaging using rotary die-cutters, flatbed die-cutters, inliners or even folding box gluers. Based on our many years of experience, we design folding cartons and die-cut packaging exactly tailored to the wishes of our customers. Sustainability and environmental friendliness are essential characteristics of corrugated cardboard and the folding cartons that are produced from it. Corrugated cardboard is the perfect recycled product, because it is recycled almost 100 percent. The folding cartons are produced from the corrugated types C, B, D, E and their combinations.

Thanks to modern printing processes, such as pre-print, offset printing or high-quality HQ flexo printing, we can give the folding carton an impressive brand image. The printed image of the folding carton can contain up to six colours. In this way, the packaging can represent your company and at the same time have an advertising effect. Please contact us if you are interested in folding cartons from DELKESKAMP and the various possibilities of application and production. We provide you with comprehensive and individual advice on which folding cartons are the optimum packaging solution for you.

Cardboard carton manufacturer

Cardboard carton manufacturer Delkeskamp: Your partner for environmentally efficient packaging according to individual requirements

You have a company and are looking for innovative packaging solutions for your products that are optimally adapted to individual needs? Then Delkeskamp cardboard carton manufacturer is your perfect contact. As a renowned German cardboard packaging manufacturer, we develop highly stable and demand-oriented packaging concepts from 100% recyclable raw material paper.

Your cardboard carton manufacturer for the best possible protection of your products

In industry and trade, optimum transport and the correct packaging of products of all kinds play a central role. Ideally, packaging solutions are optimally adapted to the respective product. As an innovative manufacturer of cardboard packaging, we have made it our business to act as a high-performance partner for companies in various industries in the field of packaging. With us you have a cardboard box manufacturer at your side who guarantees the optimal presentation of your products with ground-breaking and individual solutions. At the heart of our work as a cardboard packaging manufacturer is the development of flexible concepts for the production of packaging that take all your requirements in technical and logistical terms one hundred percent into account.

Cardboard packaging manufacturer for environmentally friendly and versatile packaging

Our innovative product portfolio includes packaging that not only offers optimum protection for your products but is also manufactured in an environmentally friendly manner and in accordance with the latest technical standards. As a cardboard packaging manufacturer with many years of experience in developing advanced and creative technologies, we produce intelligent packaging made of corrugated cardboard, allowing for an optimal use of the product for individual needs. Our environmentally efficient corrugated cardboard cartons, made from almost one hundred percent recycled raw materials, are available in various flute types and combinations and are suitable for countless applications. These range from shipping to the stabilisation of loads, transport securing and separation of individual layers on pallets. As a renowned manufacturer of cardboard packaging, we offer corrugated cardboard that can be printed using various processes as die-cut packaging and folding cartons as well as marketing instruments for your advertising presence. Companies without a corrugator can of course also obtain the innovative packaging solution from us as sheet material in the desired flute type.

Cardboard manufacturer Delkeskamp for demand-oriented communication

In our plants in Nortrup, near Osnabrück, and in Hanover, more than six hundred employees do their utmost to quickly and efficiently implement the individual requirements of all our customers in terms of packaging for products of all kinds. As a cardboard carton manufacturer, we work closely with companies in industry and food production in Schleswig-Holstein, North Rhine-Westphalia, Lower Saxony, Bremen, Hamburg, the Netherlands and Denmark. We attach great importance to targeted personal communication with our customers. This enables us to take into account all the needs and concerns of our business partners at every step of the development and production of our packaging. If you need individual packaging concepts for your products, we are your competent partner. Get in touch with us and let our experienced staff give you comprehensive advice. As your cardboard packaging manufacturer, we look forward to providing you with all our knowledge of the technological possibilities of using corrugated cardboard and paper as well as foam and to developing the optimum environmentally efficient packaging solution for your products.

Foam DENOPOR®

Highly sensitive or valuable goods often need special protection during transport and storage. Moulded parts made of expandable polystyrene (EPS) offer this safe protection. They embed the product precisely, thus protecting it from vibration, cold, heat or moisture, or contribute to the product itself as a technical component. They are also odourless, tasteless and food-neutral and can be recycled without any problems.

At our site in Nortrup we produce packaging, load carriers and technical parts from EPS (Styropor®), Neopor® and Piocelan®. MORAplast s.r.o. in the Czech Republic also manufactures products made of expandable polypropylene (EPP).

Discussion about plastic waste

Plastic as a valuable material

Plastic is actually clean! Yet hardly any other material is currently being criticised as much as this one: "plastic waste" has become a buzzword, giving plastic products the malus of being inferior or even harmful. This impression is reinforced by dramatic images that show the extent of the rubbish slicks on our oceans and the suffering of the marine animals affected. These images unquestionably bear witness to a problem the solution of which requires joint action by consumers, trade, industry and politics worldwide.

Nevertheless, plastic is also a very valuable material that performs a variety of tasks. Since we produce plastic or moulded parts from foam ourselves, we have an interest in a good image.

Anyone who would like to contribute to this can take a look at the Newsroom Plastic Packaging page or ideally ‘like’ the Facebook page or give this page a thumbs up.

Thank you very much.

newsroom.kunststoffverpackungen.de facebook.com/Newsroom.Kunststoffverpackungen

Piocelan - "foam" at Delkeskamp

Packaging, technical parts and load carriers

When we at Delkeskamp talk about our product range, you read paper, corrugated cardboard and foam everywhere. But what exactly do we mean by the generic term "foam"?

Technically speaking, we are talking primarily about polystyrene. But a few decades ago, BASF succeeded in inventing the special feature of being able to combine this raw material with a blowing agent. In this way, a small pearl, the size of a grain of sand, could be ‘blown up’ into a large pearl up to the size of a pea with the help of steam. And this is how the technical term "expandable polystyrene", or EPS for short, came about. What really became known, however, was BASF's brand name "Styropor®", which has almost developed from a trade name to a generic term in Germany.

Foam and its names

There have been, and still are, several attempts to find other terms as a synonym for EPS. For 4 years now, instead of Styropor®, the name "airpop®" has been heard frequently. The reason is that efforts are being made to develop a uniform European name for the EPS product.

Thus, for example, "particle foam" or "hard foam" is also often used. The advantage of these terms is that other products with similar functions and production processes can also be grouped under them. These are for example EPP (expandable polypropylene) or Piocelan. EPS, EPP and Piocelan differ mainly in their material properties in terms of hardness, elasticity, resilience, etc. However, the difference is also in price. A product such as EPP, which offers many advantages in terms of material properties, is of course also significantly more expensive. But here too, there is an alternative. Piocelan! It has almost identical material properties and is usually slightly cheaper than EPP!

Piocelan as a cheap and high-quality alternative to EPP

So, if you are looking for packaging that combines high quality with low cost, you should choose Piocelan solutions. As a foam, Piocelan combines the strengths of the raw material EPS/ Styropor® with those of polyethylene (PE) or polypropylene (PP). Piocelan is therefore ideal for transporting and storing fresh or sensitive products. Piocelan has the excellent shock absorption and chemical resistance characteristic of PP and PE. Piocelan also has the low density of EPS (polystyrene). Unlike Styropor®, Piocelan does not crumble, but is crack resistant. In this way, it offers high-quality product protection and keeps the product warm, cold or dry as required. Due to Piocelan’s durability, entire packaging as well as moulded parts or carriers made of this foam can be reused. Piocelan is thus more environmentally friendly. Moreover, the foam also withstands difficult environmental conditions. It therefore offers a wide range of applications and is consequently the right choice in terms of economy and performance in the packaging sector.

Styropor®, Piocelan and other foam products at Delkeskamp

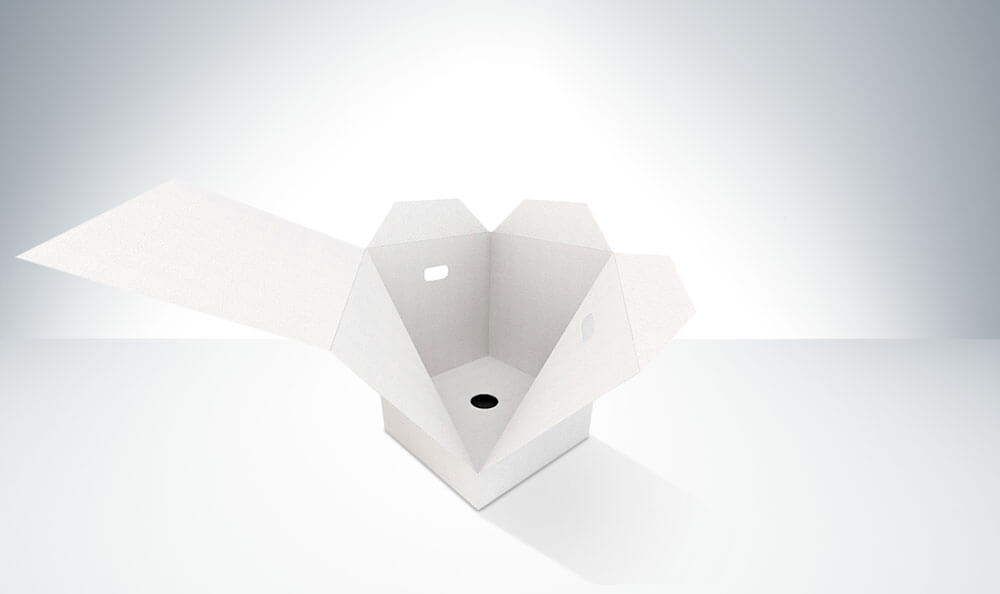

In contrast to the building industry (insulation boards), we at Delkeskamp are primarily concerned with moulded parts, i.e. individually designed shapes that fulfil a specific function. In terms of functions, we distinguish between packaging, technical parts and load carriers. In the case of packaging, the focus is on the protective function against transport damage and climate variation (heat/cold). A moulded part made of EPS adapts itself to the goods to be protected and therefore develops the perfect protective effect. The internet mail order business for temperature-sensitive goods such as food is currently gaining particular importance. Terms such as "cool boxes, insulation boxes, climate control boxes or fish crates" describe flexibly designed boxes made of Styropor® that protect perishable goods. Technical parts fulfil a function in or on an end product and are therefore themselves part of the product. And load carriers made of Styropor® are part of logistical processes which, for example, safely transport components of a product within a production process.

In addition to the individually and flexibly developed moulded parts, there are also standards that have proven themselves, for example, with regard to protective functions. Typical examples are packaging corners, packaging angles or edge protections made of Styropor®.

Insulated boxes at Delkeskamp

DELKESKAMP: high-quality insulated boxes for the transportation of sensitive goods

As an experienced manufacturer of various packaging solutions and raw materials, we always offer our customers the optimal solution for their packaging requirements. A wide range of insulation boxes is available for the tailor-made transportation of goods. Individually configured packaging solutions such as insulation boxes are also available from Delkeskamp in EPS and Piocelan. Both materials adapt perfectly to the packaged goods. They protect against transport damage and temperature. EPS and Piocelan are therefore particularly suitable for products that have to stay freshly cooled or kept warm. EPS and Piocelan also adapt perfectly to the shape of sensitive packaged goods and provide optimum protection during transport. Internet traders would not be able to run their successful e-commerce businesses without EPS and Piocelan insulation boxes. Fresh food can be shipped with insulated boxes and sensitive customers can be sure to get the freshness they expect. And satisfied customers also sustainably reduce return rates.

Insulation boxes: The flexibly designed box made of Styrofoam

Our modern development department designs, and our modern machinery produces insulation boxes according to your wishes. A differentiation is made between individualised moulded parts and standardised parts. The latter have also proved their value when transporting sensitive goods, for example in the form of packaging corners and angles or with careful edge protection. All these standard parts can also be made of Styrofoam. They provide cushioning within the outer packaging and are therefore particularly recommended for goods which must be transported in a well-fixed position or are made of fragile materials. As already mentioned, it is especially the standardised insulation boxes made of EPS (polystyrene) or Piocelan that keep cool, warm, dry and safe during transport and storage. Today, the term "Airpop" is often used as a uniform designation for products made from these raw materials. This was an attempt to provide the industry with a uniform standard, but in general the materials are identical.

Insulated boxes are therefore high-quality packaging, which retailers and distributors in particular like to use for demanding packaging tasks. Protect, cool, warm or adapt perfectly to a shape to be protected - this is what insulation boxes as packaging do, but also technical parts made of EPS and Piocelan. On the way to the dealer, to the end customer or generally between different stops along the transport route - Delkeskamp insulation boxes always meet the individual requirements of the customers. It goes without saying that good transport protection with fewer complaints is also more economical.

Insulation boxes: Contact us, we will be happy to discuss everything else personally!

Do you need insulation boxes, or would you like to learn more about our production, individual processes or the later uses? Simply contact our team! We would be pleased to inform you in a personal conversation why insulation boxes are also an enrichment for your company. In the interest of safe shipping, you are welcome to check our quality standards.